China CNC Milling » Blog » Quality Control and Technological Innovation in the Manufacturing of Large-Scale Thin-Walled Stainless Steel Heat Exchangers

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

With the rapid development of the chemical industry, the performance and manufacturing quality of heat exchangers have become key indicators for evaluating equipment standards.

This paper focuses on a large, thin-walled stainless steel heat exchanger used in a chemical plant.

It features an inner diameter of φ3400 mm, a wall thickness of 18 mm, a total length of 14.5 m, and a total weight of 90 t.

The heat exchanger is primarily constructed from S30408 material.

Drawing upon practical manufacturing experience, this study examines the challenges encountered during production.

It also proposes key quality control technologies and improvement measures.

Quality Control for Cylinder Forming and Straightening

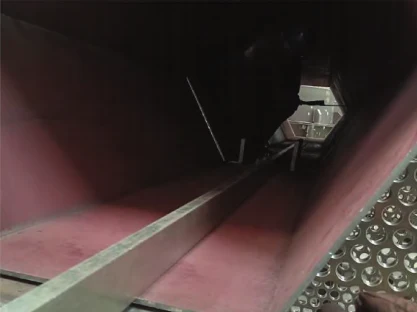

In the manufacturing process of large thin-walled stainless steel heat exchangers, cylinder forming and straightening constitute fundamental and critical steps.

During the forming process, the following key points require particular attention:

1. Select an appropriately matched plate rolling machine to ensure the sheet metal remains undamaged during forming.

The performance of the rolling machine directly impacts the quality of the rolled sheet.

Improper selection may cause surface defects such as scratches or dents during rolling, compromising the cylinder’s quality.

2. Strictly control the rolling speed.

Excessively high speeds can easily create wave patterns on the cylinder.

These patterns severely affect its roundness and straightness, which in turn compromise the overall performance of the heat exchanger.

Appropriate rolling speed ensures the formed cylinder meets design specifications.

3. Perform precise calibration on the rolled cylinder.

Calibration must guarantee the cylinder’s roundness and straightness comply with design requirements, which is a critical prerequisite for the heat exchanger’s normal operation.

Only cylinders calibrated with precision can provide a solid foundation for subsequent processes like tube rack assembly and tube insertion.

Quality Control in Selecting Pipe Rack Assembly Methods

Given the site constraints limiting internal pipe rack assembly, crane operations are impossible.

Internal work must rely solely on manual labor or tools like hand chain hoists.

Under these conditions, designing the process for external pipe rack assembly fully leverages crane capabilities, significantly boosting operational efficiency.

Implementing the external pipe rack assembly plan avoids numerous difficulties caused by confined spaces.

It also overcomes the inability of cranes to access internal work areas, significantly improving both the efficiency and quality of pipe rack assembly.

Through rational planning of workflows and the use of mechanical equipment like cranes, pipe rack assembly can be completed with greater precision.

This reduces errors that may arise from manual operations, ensuring the accuracy and stability of the assembled pipe racks.

Quality Control in Assembly Process

Center Cylinder Assembly

To ensure precision, first align a baffle plate with a section of the center cylinder.

Use a lifting fixture to determine their relative positions.

This fixture enables precise adjustment of the height and levelness between the center cylinder and baffle plate, guaranteeing assembly accuracy.

The assembled center cylinder is then hoisted onto the support frame.

Positioning is further refined using tools such as straight edges and feeler gauges.

After confirming accuracy, the assembly is secured.

These tools enable operators to visually and precisely verify the center cylinder’s positioning.

Through meticulous adjustments, the assembly precision meets design specifications.

Baffle Plate Assembly

The alignment accuracy of baffle plate holes is critical for subsequent pipe insertion.

During assembly, release the fixation to the central cylinder and use jacks to adjust left-right balance.

The jack enables flexible adjustment of the baffle plate position to ensure lateral balance meets specifications.

Additionally, ensure the baffle plate spacing is slightly greater than the final paper size. This facilitates inserting spacer tubes before installing tie rods.

Proper baffle plate spacing simplifies the installation of spacer tubes.

It ensures a rational overall piping layout and enhances both the efficiency and quality of the pipe threading process.

Tie Rod and Tube Sheet Assembly

After completing the tube rack assembly, the tube rack is lifted into the shell using cantilever beams.

Due to the tie rods’ length of 8 meters, shims are used during assembly for support and positioning, enabling operators to install the tie rods with greater precision.

The shims are removed after the tube rack is fully seated.

Manual visual inspection assists in aligning the threaded holes, ensuring accurate tie rod assembly.

Through careful manual observation and adjustment, deviations during tie rod assembly can be promptly identified and corrected.

This ensures precise alignment between the tie rod and the tube sheet threaded holes.

It guarantees tie rod assembly quality and ultimately safeguards the stability and reliability of the entire heat exchanger structure.

Quality Control Outcomes

By effectively implementing the aforementioned quality control measures, manufacturers have significantly enhanced the quality of this heat exchanger.

The shell’s roundness and straightness strictly comply with design requirements.

Precision in the tube bundle assembly and fitting processes is robustly ensured, resulting in stable and reliable overall performance of the heat exchanger.

During the cylinder rolling and straightening stages, engineers strictly controlled the rolling speed.

They selected appropriate rolling machines and applied precise straightening measures.

These actions enabled the cylinder to achieve high standards across all metrics.

Optimized tube rack assembly plans enhanced operational efficiency and precision.

Meticulous control during the tube insertion process ensured assembly accuracy for all components.

These achievements enable the heat exchanger to meet the demands of chemical production, providing reliable assurance for the stable operation of the chemical industry.

Conclusion

This paper conducts an in-depth study on the key quality control points and measures in the manufacturing process of large thin-walled stainless steel heat exchangers.

It proposes a series of innovative improvement solutions that effectively enhance manufacturing quality.

These findings hold significant reference value for the production of similar heat exchangers and contribute to advancing equipment manufacturing technology in the chemical industry.

In future heat exchanger manufacturing, engineers can leverage the experience outlined herein.

They can continuously optimize manufacturing processes and elevate quality control standards.

This approach will provide superior equipment support for the sustainable development of the chemical industry. Simultaneously, engineers must continuously monitor technological advancements.

They must pay ongoing attention to the application of new materials and processes in heat exchanger manufacturing.

This will enable adaptation to the chemical industry’s growing demands and propel the sector toward greater efficiency, environmental sustainability, and intelligent development.

Through persistent exploration and innovation, engineers will inject new vitality into equipment manufacturing technology for the chemical industry.

This approach will, in turn, promote its high-quality development.